C2 Joint Fill 600ml Dual Cartridge Any Colour

C2 Joint Fill 600ml Dual Cartridge Any Colour

SKU:C2JF-600C

Order by 2pm for Same Day Dispatch

Order by 2pm for Same Day Dispatch

Couldn't load pickup availability

Product Information

PRODUCT DESCRIPTION

Composition: C² Joint Fill is a rapid setting polyuria liquid of 100% solids content. When cured, C² Joint Fill is a gray, rubberlike solid with a hardness of Shore A88-92.

Basic Use: C² Joint Fill was developed to fill and protect joints in trafficked industrial and retail concrete floors. Its primary function is to support traffic and protect joint edges. C² Joint Fill is intended for use where final temperatures are from 0°C (32°F) to + 49°C (120°F). Other Uses: C² Joint Fill is also ideal for filling random cracks in industrial floors

ADVANTAGES

C² Joint Fill is rated Heavy Duty. Unlike softer polyureas, C² Joint Fill higher shore hardness provides greater edge protection and support

C² Joint Fill is 'Rapid-Setting'. At 21°C (70°F) it can be opened to full traffic in as little as (60) minutes and light traffic in (30) minutes

C² Joint Fill maintains a consistent color profile and resist fading and other discoloration under normal conditions

C² Joint Fill is 'Non-Staining'. In normal slab surface conditions, C² Joint Fill does not exhibit residual concrete staining often associated with semi-rigid fillers

C² Joint Fill is ideal for use in Stained/Polished concrete floors. C² Joint Fill can be used to fill joints and cracks in polished concrete floors and will not smudge or smear during grinding/polishing

COLOUR

Standard color is Standard Gray. C² Joint Fill is also available in color matches for our C² Tint? and C² Color Hard dyes. Please see C² Joint Fill color match chart for details.

PACKAGING

C² Joint Fill is available in 600ml (300x300) dual cartridge kits for use with a Dual Cartridge Gun. C² Joint Fill is also available in bulk kits of 36 Liters (2- 18 liter units A & B).

USDA/FDA Regulated Facilities

C² Joint Fill is acceptable for use in floors subject to USDA and FDA inspection and regulation.

USGBC LEED Projects

C² Joint Fill contains no VOCs (0%) and is fully compliant with USGBC LEED green building standards. Food Related Facilities C² Joint Fill is acceptable for use in facilities regulated by USDA/FDA. Contact us to discuss project details if contamination is a concern.

LIMITATIONS

C² Joint Fill is not recommended for use under VCT or other non-breathing flooring systems

C² Joint Fill is designed for interior use and may not be suitable for outdoor applications due to thermal movement

C² Joint Fill is not designed for use in temperatures below 0°C (32°F)

C² Joint Fill may exhibit bubbling and/or compromised adhesion if concrete or ambient moisture levels are excessive

INSTALLATION

Correct Joint Design/Installation: C² Joint Fill should be installed full joint depth in sawcut construction/control joints (or 51mm (2") min. in saw-cut joints exceeding 2" in depth) per PCA and ACI guidelines.

In construction (formed) joints that are not saw-cut, C² Joint Fill? should be installed at a minimum 51mm (2") depth. DO NOT USE COMPRESSIBLE BACKER ROD IN STANDARD SAW CUT CONSTRUCTION/CONTROL JOINTS! Rod may be used 51mm (2") down in construction joints or saw cut joints exceeding 51mm (2") ONLY.

When to Install: The installation of C² Joint Fill should be deferred as long as possible after slab placement and should not be installed prior to 30 days to ensure adequate adhesion. ACI recommends a slab cure of 60-90 days or longer to permit for greater concrete shrinkage/joint opening, lessening the expected incidence of joint filler separation. Ambient areas should be stabilized at final operating temperature prior to installation, refrigerated/frozen goods areas stabilized and held for an additional 7-14 days or longer if possible.

Joint Preparation: Joints should be completely free of saw laitance, dirt, debris, coatings/sealers and frost or visible moisture. Joint cleaning procedures must accomplish the removal of all of the above. Failure to do so will compromise adhesion. Simply ?raking? debris out of the joint is not an acceptable cleaning method. Preferred methods of joint cleaning include using a dustless concrete saw with diamond blade (ensure blade is slightly wider then joint or clean both sides) or sandblasting. No primer is needed. If unusual conditions are present, contact Crete Colors for assistance.

Choking off the base of the joint is normally not required due to C² Joint Fill? rapid set. Do not use compressible backer rod in saw cut joints less than 51mm (2?) deep. Prior to Dispensing: Thoroughly read MSDS and complete installation instructions prior to opening containers or attempting to dispense. C² Joint Fill? must be dispensed with dual-feed power dispensing equipment, or with pre-filled dual-dispense cartridge kits. Manual dispensing is impractical due to short working life (1-2 minute gel time). Power dispensing systems should be set to a 1:1 ratio by volume. If installing in cooler temperatures, material should be maintained at a minimum temperature of 24°C (75°F) for best results. We recommend the use of a ½? (about 13mm) diameter (ID) static mixer with 32 elements or more for material dispensing and proper mix. We strongly recommend performing periodic ratio checks on power dispense units to ensure proper cure. Material provided in pails should be thoroughly mixed to redistribute and settlement that may have occurred during shipping or storage. Cartridges should be shaken aggressively to accomplish the same.

Prior to Dispensing: Thoroughly read MSDS and complete installation instructions prior to opening containers or attempting to dispense.

C² Joint Fill? must be dispensed with dual-feed power dispensing equipment, or with pre-filled dual-dispense cartridge kits. Manual dispensing is impractical due to short working life (1-2 minute gel time). Power dispensing systems should be set to a 1:1 ratio by volume. If installing in cooler temperatures, material should be maintained at a minimum temperature of 24°C (75°F) for best results. We recommend the use of a ½? (about 13mm) diameter (ID) static mixer with 32 elements or more for material dispensing and proper mix. We strongly recommend performing periodic ratio checks on power dispense units to ensure proper cure.

Material provided in pails should be thoroughly mixed to redistribute and settlement that may have occurred during shipping or storage. Cartridges should be shaken aggressively to accomplish the same. Pump tanks, lines and dispensing manifold should be clean and free of any residual materials remaining from previous filler installations. Dispensing: Joints can be filled in one or two passes, depending upon joint depth and dispensing tip used. Preferred method is to fill from bottom to top using a dispensing tip that fits into the joint. Take care not to entrap air bubbles. Slightly overfill the joint, leaving a crowned profile, and allow to cure.

Finishing: The crown may be easily razored off as early as 15 minutes after placement, depending upon temperatures. We recommend testing various shave times to find the optimal shave which results in a filler profile that is flush with the floors surface and free of any film from material overfill. If shave time is substantially delayed or if temperatures are low, C² Joint Fill? shaving process may be more labored.

Should filler cure below the floor surface (due settlement into the void at base od joint, etc.), remove top 13mm (1/2?) of filler and re-apply C² Joint Fill?.

Grinding/polishing operations should be deferred for one hour or more after placement.

Clean-Up: Spills of unmixed components can be cleaned up with solvent (MEK, denatured alcohol, etc.) or scraped/shaved off floor and tools if cured

If using dual-component cartridges: Prepare cartridge for dispensing with static mixer and flow restrictor per kit instructions. Material should be dispensed at a moderate pace using steady pressure. After dispensing begins keep cartridge pointed down at all time to prevent cross contamination. Keep a waste container (disposable cup) handy to purge C² Joint Fill? liquid at start of application and/or if dispensing is delayed for more than 45 seconds (to avoid cured material in mixer tip).

MAINTENANCE

Once cured, C² Joint Fill is basically maintenance free. If joints should open after installation, fill voids with additional C² Joint Fill.

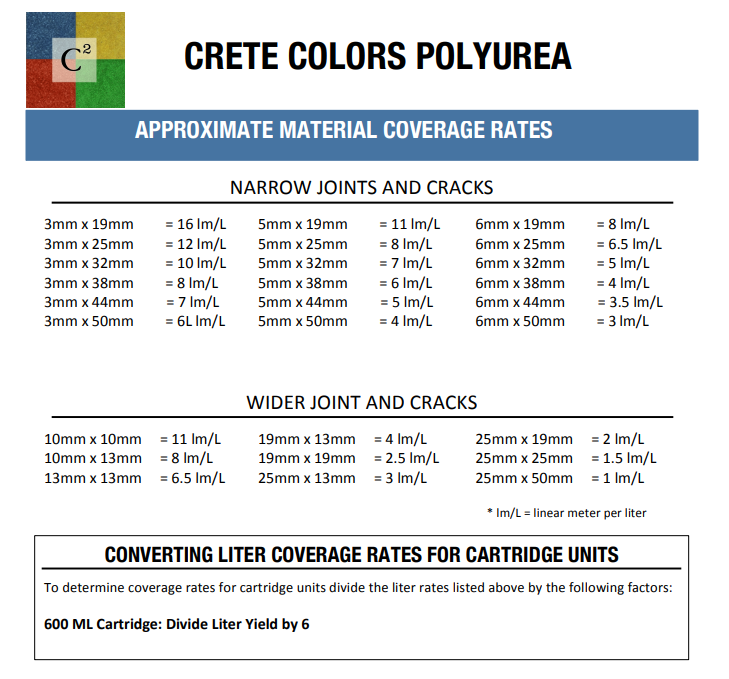

See Photos for Coverage Guide

Store Locator

Store Locator Login

Login

Cart

Cart