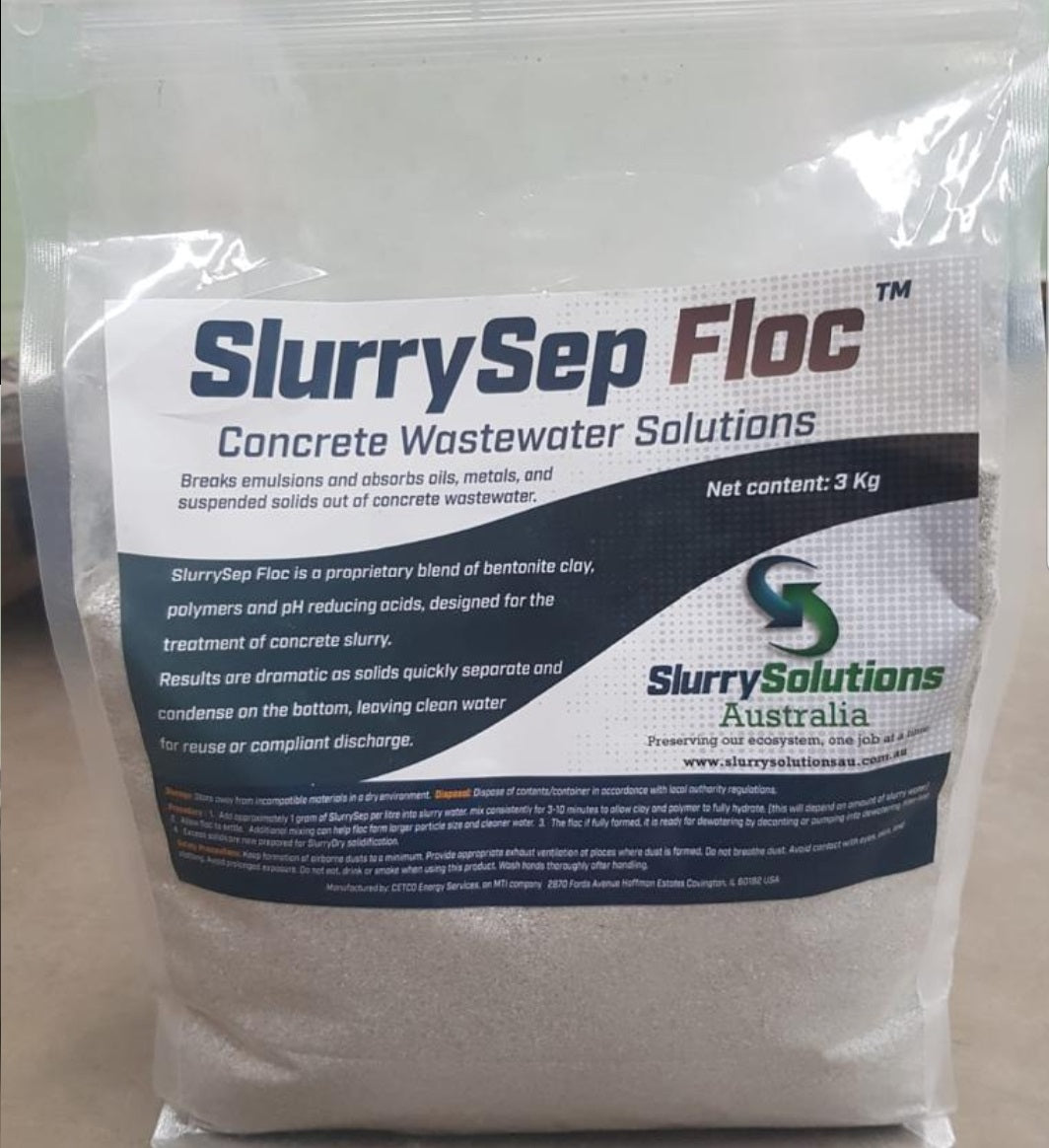

SlurrySep Floc 3kg - Concrete Wastewater Solutions

SlurrySep 3kg Breaking Agent(Discontinued)

SKU:SS-SEP-3

Order by 2pm for Same Day Dispatch

Order by 2pm for Same Day Dispatch

Couldn't load pickup availability

Product Information

SlurrySep Floc

Concrete Wastewater Solutions

SlurrySep breaks emulsions and absorbs oils, metals and suspended solids out of concrete wastewater. It is a proprietary blend of bentonite clay, polymers and pH reducing acids designed for the treatment of concrete slurry. Results are dramatic as solids quickly separate and condense on the bottom, leaving clean water for reuse or compliant discharge.

SlurrySep Flocking Agent

SlurrySep is a proprietary blend of bentonite clay, polymers and pH reducing acids is designed for the treatment of concrete slurry. Results are dramatic as solids quickly separate and condense on the bottom, leaving clean water for reuse or compliant discharge.

Procedure:

1. Blend 1-2 lbs per 200 gallons. Add SlurrySep into the slurry and mix consistently for 5-10 minutes to allow clay and polymer to fully hydrate.

2. Allow floc to settle. Additional mixing can help floc form larger particle size and cleaner water.

3. Once the floc if fully formed, it is ready for dewatering by decanting or pumping into dewatering filter bag.

4. Excess solids are now prepared for SlurryDry solidification.

SlurrySep provides rapid settling of concrete and stone slurries

SlurrySep Clay Based Separating Agents

Wastewaters contain a mixture of solids (both suspended and colloidal), dissolved metals and organic compounds. While there are many options available to remove these contaminants, most involve multiple steps and a considerable amount of time for the process.

The traditional approach to pre-treating waste streams for discharge or re-use typically involved:

- Adjusting pH to break oil emulsions and precipitate dissolved metals;

- Adding coagulants to aid agglomeration of metals into small masses;

- Adding polymers (polyelectrolytes) to help form larger masses (flocs) for removal, as well as clarify effluent.

SlurrySep eliminates these laborious, multi-step processes. All SlurrySep formulas are a non-hazardous blend of sodium bentonite clay, minerals, and other proprietary resources. SlurrySep offers generators of various waste streams a safe, simple, and cost-effective means for pre-treatment and disposal. In addition, SlurrySep eliminates the need for handling and storing liquid chemicals used in traditional wastewater treatment systems.

SlurrySep process can be described as follows:

- Acidic components release and cause oily particles to de-emulsify and separate from water.

- Cationic polymers attract any remaining oil and highly charged anions.

- A base component helps precipitate metal hydroxides.

- Wastewater is now in a condition known as flocculation, where cationic molecules and metallic ions are all attracted to the clay and form larger masses.

- Clay particles begin to stick together, entrapping other components and surrounding them completely, a process known as micro-encapsulation.

- Encapsulated particles are ready to be de-watered and disposed of properly as non-hazardous waste.

- This entire process is completed within minutes and does not require any operator intervention or ?jar testing.? SlurrySep combines all components of traditional pre-treatment into one single step.

Slurry Solutions SlurrySep Product

- Non-reactive, non-hazardous (as opposed to liquid caustic and acidic coagulants).

- Packaged in 50# bags or bulk super sacks for easy storage and movement.

- Easier containment /clean-up in case of a spill.

- Semi-granular and granular blends minimize exposure to fine dust.

- It can be easily introduced to a waste stream with an auger type dry feeder.

Decrease Process Time

- SlurrySep combines multiple functions of traditional treatment scheme almost simultaneously, into one simple step.

- Base clays used in all SlurrySep blends are cationically charged, allowing faster precipitation and settling of metal hydroxides.

- The typical treatment time required for the full reaction is less than ten minutes.

Versatile Technology

- Effective treatment of different types of waste streams with a pH of 2-12.

- SlurrySep can utilize in batch or in-line treatment schemes and in most cases with existing equipment.

- Removes /lowers heavy metals, TSS, oils and other organic /inorganic matter.

- Several blends to accommodate various waste streams and conditions.

Cost-Effective

- SlurrySep requires very little operator interface.

- Only one product to add and maintain.

- Generate a solid waste that is microencapsulated and considered non-hazardous.

- SlurrySep is a clay-based product, which is easily pressed and dewatered.

Consistent Results

- Clay-based products are more forgiving if overdosing occurs.

- High affinity for metals, organics, and other contaminants.

- Proven technology for nearly 30 years.

Store Locator

Store Locator Login

Login

Cart

Cart