Uneven concrete surfaces, such as footpaths that have been affected by tree roots, subsoil movement or heavy vehicles breaking up the surface pose significant liability issues to the property owner. Addressing these issues promptly is crucial for safety and compliance with regulations. In our experience the most effective and long lasting method for eliminating these hazards is concrete grinding, which smooths out the transition between the high and low side of the uneven surface and therefore removing the trip hazard.

Selecting The Right Equipment

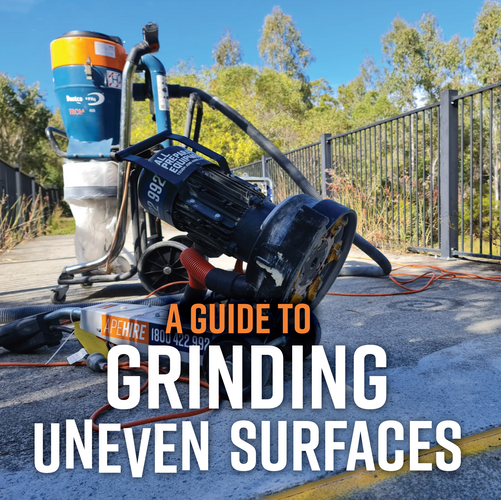

For a lippage of approximately 10 mm over a 900 mm width, the Schwamborn DSM250 is an optimal choice. This grinder, equipped with six aggressive diamond shoes, ensures smoother operation, especially when overhanging the edge of the lippage. In a recent project, this setup removed the trip hazard in just over four minutes. It's also much more suited than the alternative, a scarifier. The DSM250 can overhang the edge – a traditional scarifier has a wheelbase with cutter drum in the centre of the machine which means either the front or rear wheels can drop onto lower section of path causing extreme stress on the scarifier. You can find the Schwamborn DSM250 and suitable diamond shoes on our website. Call us on 1800 422 992 for advice on your specific project.

Choosing the Appropriate Diamond Tooling

The selection of diamond tooling significantly impacts both cutting speed and tool longevity. For footpath concrete, which typically has a lower MPA due to the absence of vehicular traffic, a slightly harder bond is recommended to enhance lifespan. In this scenario, 20-grit Super Economical medium soft bond (orange) diamond shoes were used. It’s essential to understand that the bond refers to the hardness of the metal holding the diamond grit together; a soft bond wears quicker, exposing the diamond grit faster. Explore our range of diamond tooling options to find the perfect match for your project.

Importance of Quality Dust Extraction

Effective dust collection is vital during the grinding process to maintain a clean work environment and protect worker health. The Dust Control Tromb 400 dust extractor pairs well with the DSM250, efficiently capturing airborne particles. Additionally, understanding the differences between L, M, and H class dust extractors is crucial for ensuring safety and compliance. Our blog post on the differences between L, M, and H class vacuums provides detailed insights to help you make an informed decision.

Power Supply Considerations

Maintaining adequate power supply is essential for optimal machine performance. Using short power supply leads with at least 2.5 mm² copper core minimizes voltage drop. For complete mobility, a portable generator like the Makinex 10Kva can provide a standalone power solution, ensuring uninterrupted operation on-site.

Advantages of Grinding Over Scarifying

While both grinding and scarifying are methods for trip hazard removal, grinding offers several benefits:

- Edge Accessibility: Grinders can reach edges more effectively, ensuring a uniform surface.

- Lightweight and Versatile: Machines like the DSM250 are lighter and require less maintenance, making them suitable for various applications, including the leading edge of the lippage.

- Surface Finish: Grinding provides a smoother finish compared to scarifying, enhancing both safety and aesthetics.

Conclusion

Addressing concrete trip hazards through grinding is an efficient and effective solution. By selecting the appropriate equipment and tooling, adhering to safety measures, and ensuring proper dust extraction, you can achieve a smooth, hazard-free surface promptly. Investing in quality tools and following best practices not only ensures compliance with safety standards but also extends the lifespan of your walkways.

For more information on concrete grinding and trip hazard removal, visit our website at www.allprep.com.au.

Note: Always ensure that all equipment is used in accordance with manufacturer guidelines and safety regulations.

Author: Elliot Moss

Store Locator

Store Locator Login

Login

Cart

Cart